Water treatment plays a vital role in ensuring clean and safe drinking water, and coagulation is one of the most important steps in this process. Coagulation is a water treatment technique that removes suspended particles, contaminants, and unwanted materials by adding special chemicals called coagulants. These coagulants destabilize and bind tiny particles together, forming larger clumps (called flocs) that can be easily separated from water.

Whether for municipal drinking water systems, industrial applications, or wastewater treatment, coagulation is essential for improving water quality, clarity, and safety.

Why is Coagulation Necessary?

Raw water often contains a variety of impurities that make it unsafe or unpleasant for use, such as:

- Turbidity (cloudiness): Caused by suspended particles like silt, clay, or organic matter.

- Microorganisms: Bacteria, viruses, and protozoa often cling to suspended solids.

- Organic Compounds: Can cause bad taste, odor, or react with disinfectants like chlorine.

- Heavy Metals: Iron, manganese, and other dissolved metals may be present.

Most of these impurities are too small and stable to settle naturally. Coagulation solves this problem by making particles stick together and become heavier, so they can be removed through sedimentation or filtration.

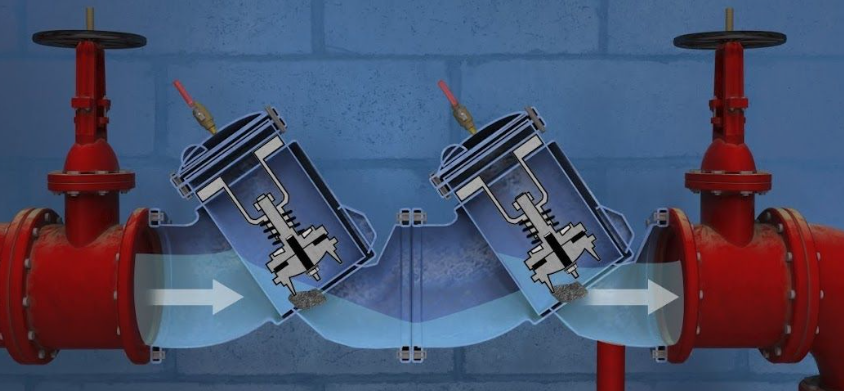

How Does Coagulation Work?

The coagulation process typically involves three main steps:

1. Coagulant Addition

Chemicals such as aluminum sulfate (alum), ferric chloride, or polyaluminum chloride (PAC) are added to raw water. These coagulants carry positive charges that neutralize the negative charges of suspended particles.

2. Destabilization

Once the charges are neutralized, the particles lose their repulsion and begin clumping together. This process is also called charge neutralization.

3. Floc Formation (Flocculation)

After destabilization, gentle mixing encourages the formation of larger, visible clumps known as flocs. These flocs can then be removed in the next stages—sedimentation, flotation, or filtration.

Common Coagulants Used in Water Treatment

Several chemicals are widely used as coagulants, each chosen based on water quality and treatment goals:

- Aluminum Sulfate (Alum): Most common, cost-effective, and efficient for turbidity removal.

- Ferric Chloride & Ferric Sulfate: Effective at lower pH levels, widely used in wastewater treatment.

- Polyaluminum Chloride (PAC): Works over a wide pH range and produces less sludge.

- Synthetic Polymers: Often used as coagulant aids to strengthen floc formation.

Benefits of Coagulation in Water Treatment

Coagulation provides several advantages in both drinking water and wastewater treatment:

- Improves Water Clarity: Removes suspended particles, silt, and turbidity.

- Enhances Filtration Efficiency: Prepares water for easier and more effective filtration.

- Reduces Pathogens: By removing particles, microorganisms attached to them are also eliminated.

- Controls Taste and Odor: Reduces organic compounds that cause unpleasant smell or taste.

- Decreases Chemical Usage: Reduces chlorine demand and by-product formation in disinfection.

Applications of Coagulation

Coagulation is widely applied across different industries and systems, including:

- Municipal Drinking Water Treatment Plants

- Wastewater Treatment Facilities

- Industrial Water Systems (e.g., paper, textile, and food processing industries)

- Stormwater Treatment to remove sediments and pollutants before discharge

Coagulation vs. Flocculation – What’s the Difference?

Though often used together, coagulation and flocculation are not the same:

- Coagulation is the chemical process of destabilizing particles by neutralizing their charges.

- Flocculation is the physical process of gently mixing to encourage particle bonding into larger flocs.

Both are crucial stages that work hand-in-hand for effective water treatment.

Challenges in Coagulation

While effective, coagulation does come with challenges:

- Sludge Disposal: Coagulation produces sludge that must be treated or disposed of safely.

- pH Sensitivity: Effectiveness depends on water pH and alkalinity.

- Chemical Costs: Continuous supply of coagulants can increase operational expenses.

- Overdosing Risks: Too much coagulant can cause restabilization of particles instead of removal.

These challenges are managed through careful jar testing, dosage control, and modern automation systems.

Modern Advances in Coagulation

Technology continues to improve traditional coagulation methods. Some modern innovations include:

- Advanced Coagulants (like PAC): More efficient, reduce sludge, and work across wider conditions.

- Green Coagulants: Plant-based or biodegradable coagulants for eco-friendly treatment.

- Automated Dosing Systems: Real-time sensors adjust chemical dosages to optimize performance.

- Hybrid Processes: Combining coagulation with membrane filtration or advanced oxidation for superior results.

Final Overview

Coagulation is a cornerstone of water treatment, ensuring clean, safe, and aesthetically pleasing water for residential, commercial, and industrial use. By destabilizing and clumping fine particles, coagulation enhances sedimentation, filtration, and disinfection, making water treatment more effective and efficient.

As water challenges grow worldwide, modern coagulation methods continue to evolve, offering sustainable, cost-effective, and reliable solutions for cleaner water.